Name of Industry: Bharat Heavy Electricals Limited (BHEL)

Date of Visit: 29-07-2019

Total No. of Student: 40

Total No. of Faculty: 03

Faculty Coordinator: Mr.M.Sri Kiran, Mr.Shafath Ali & Miss.T.Sharvani

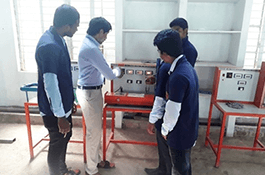

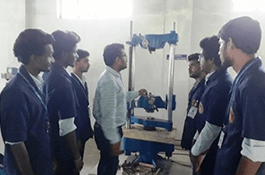

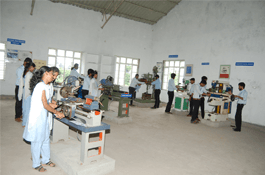

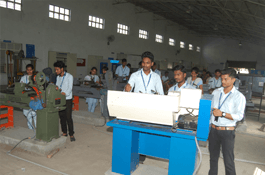

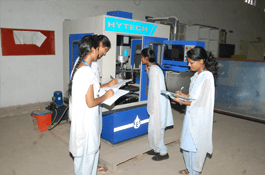

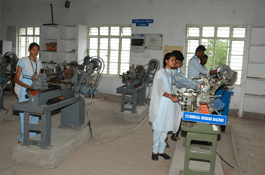

The department of mechanical engineering has arranged an industrial visit to Bharat Heavy Electricals Limited (BHEL) for 4th Year & 3rd Year students. The visit was organized with the prior permission and guidance of hon. Principal and Head of Department.

Conference Aim & Objectives:

The conference aims to bring Scientists, Engineers, Academicians, Researchers and Professionals on to a common platform to exchange and share most recent innovations and new research outcomes on all aspects of Science, Technology, Engineering, and Management. The objectives of the conference are:

Ø To allow researchers, students and engineers for fruitful discussions, and presentation of new findings confined to the conference topics.

Ø To understand and promote the emerging global trends in Engineering, Technology & Management.

Ø To provide interdisciplinary forum for Scientists, Engineers, Academicians, Researchers and Professionals to navigate the scope for future research.

Ø To arrange keynote addresses by subject experts, invited talks and regular technical sessions for research papers presentation.

The conference will provide a chance to interact with Scientists, invited speakers and experts of different areas. Their rich experience and expertise will be an added advantage of this conference. All the papers will be double blind reviewed to ensure consistency in quality and academic depth.

| S.NO | DATE | NAME OF THE EVENT | NAME OF THE SPEAKERS | NAME OF THE ORGANIZERS |

|---|---|---|---|---|

| 1 | JULY (16-17) 2019 | MECHANICAL PROJECT EXPO | SRI CHARAN LAKKARAJU & BALA PEDDIGARI | M.JAWAHAR, B.SHIVA KUMAR, MD.SHAFATH ALI. |

| 2 | JULY 29,2019 | INDUSTRIAL VISIT-BHEL | M.SRIKIRAN, MD.SHAFATH ALI. |

|

| 3 | AUG 5th, 2019 | ORIENTATION & PROJECT EXPO | M.JAWAHAR, MD.SHAFATH ALI. |

|

| 4 | AUG 15th, 2019 | INTITA INNOVATION, JNS GROUND, HNK |

M.JAWAHAR, B.SHIVA KUMAR, MD.SHAFATH ALI |

|

| 5 | AUG 29th, 2019 | A ONE DAY WORKSHOP ON FEM | GM.RAJAMAHENDRA, SIMULATION ENGINEER, YUCAN TECHNOLOGIES BENGALURU. |

M.JAWAHAR, M.SRIKIRAN, MD.SHAFATH ALI |

| 6 | SEPT (23-24),2019 | SAE INDIA STUDENT CONVENTION TIER-1 COMPETITIONS | M.JAWAHAR, MD.SHAFATH ALI |

|

| 7 | 11th Jan 2020 | HMT Industrial Visit | Mr. NV. Gurva Reddy, HMT. | Mr.Md. Shafath Ali Nawaz, Mr.Ch.Jeevan Reddy, Ms.E.Sucheritha |

| 8 | 14th March 2020 | A Hands on workshop On 3D printing workshop | Mr. M. Shravan Kumar, Design Engineer & MD, Flash Maker. | Mr.M.Jawahar, Mr.Md. Shafath Ali Nawaz, Mr.B.Sandeep |

| S.No | Date | Name of The Event | Name of the Speakers | Name of the Organizers |

|---|---|---|---|---|

| 1 | March 15, 2019 | Mechanical Project Expo | Dr.Ch.Sridhar Reddy, Professor, JNTUCEH Manthani | B.Hemasunder, M.Jawahar |

| 2 | Feb 12, 2019 | A One Day Workshop on "Mechanical Engg Design Cad" | Mr.Md.Sameer, BDM, CANTER CADD INDIA PVT LTD, Hanamkonda | M.Jawahar, B.Hemasunder |

| 3 | Jan 25, 2019 | Guest Lecture on Finite Element Methods for III Year Students | Dr.Ch.Sridhar Reddy, Professor, JNTUCEH Manthani | B.Hemasunder, M.Jawahar |

| 4 | Oct 19, 2018 | Guest Lecture on Metrology & Instrumentation for III year Students | Dr.Ch.Srinivas, Professor & Principal, VCE Karimnagar | B.Hemasunder, M.Jawahar |

| 5 | Oct 11-12, 2018 | A two day national level workshop on "Design and Simulation for next generation Applications" | Mr.Y.Naresh Design Engineer, Build CAD Technical Services, Hyderabad | B.Hemasunder, M.Jawahar |

| 6 | Sept 19, 2018 | SAE INDIA Student Convention Tier-1 Competitions | B.Hemasunder, Asst Profesor, JITS Narsampet | B.Hemasunder, M.Jawahar |

| 7 | Sept 7, 2018 | A one day Visit-ARCI Hyderabad | Dr.Gururaj Telasang, Scientist D ARCI Hyd | B.Hemasunder |

| S.No | Name of the Teacher | Name of the FDP | Sponsored Authority | Dates of the Programme |

|---|---|---|---|---|

| 1. | Dr.Gururaj Telasang, Scientist, ARCI Hyd | Expert Lecture on "Additive Manufacturing &ItsApplications". | JITS | 7/10/2017 |

| 2. | Md.Jaheeruddin, HVAC Solutions Hyd | A national level Workshop on "REVITMEP(HVAC)" | JITS | 18/09/2017 |

| 3. | Mr.B.Hemasunder, Asst.professor | Engineers Day Celebrations | JITS | 15/09/2017 |

| 4. | Mr.B.Hemasunder, Asst.professor | Teachers Day Celebrations | JITS | 5/9/2017 |

| ORGANIZING SOCIETY | DATE | Name of the department | NAME OF THE EVENT | Name of the Organizers |

|---|---|---|---|---|

| JITS Narsampet | 10th Feb, 2018 | Mechanical Engineering | A one day workshop on 3D Printing | Mr.P.Vamshi Krishna, Mr.A.Ashok kumar 3Dfy Designing & Printing Servises Hyd. |

| JITS Narsampet | 7th Oct, 2017 | Mechanical Engineering | Expert Lecture on Additive Manufacturing & Its Applications | Dr.Gururaj Telasang Scientist, ARCI Hyd & Mr.B.Hemasunder |

| JITS Narsampet | (18TH SEPTEMBER '2017) | Mechanical Engineering | A national level Workshop on REVIT MEP (HVAC) | Dr.V.Vikram Reddy, M.Jawahar, B.Sandeep |

| SAE Jayamukhi Collegiate club | (15TH SEPTEMBER '2017) | Mechanical Engineering | Engineers Day Celebrations | Dr.V.Vikram Reddy, B.Hemasunder |

| SAE Jayamukhi Collegiate club | (5TH SEPTEMBER '2017) | Mechanical Engineering | Teachers Day Celebrations | Dr.V.Vikram Reddy, B.Hemasunder |

| SAE Jayamukhi Collegiate club | (1ST SEPTEMBER '2017) | Mechanical Engineering | "How Things Work" | Dr.V.Vikram Reddy, B.Hemasunder |

| SAE Jayamukhi Collegiate club | (19th AUGUST '2017) | Mechanical Engineering | Auto Quiz Competition | Dr.V.Vikram Reddy, B.Hemasunder |

| SAE Jayamukhi Collegiate club | (5th AUGUST '2017) | Mechanical Engineering | Case Studies Presentations | Dr.V.Vikram Reddy, B.Hemasunder |

| SAE Jayamukhi Collegiate club | 29th JULY '2017 | Mechanical Engineering | Team Building Activities | Dr.V.Vikram Reddy, B.Hemasunder |

| SAE Jayamukhi Collegiate club | 10/7/2017 | Mechanical Engineering | Inauguration of SAE Jayamukhi Collegiate club | Dr.V.Vikram Reddy, B.Hemasunder |

About the event: The department of mechanical Engineering of SAE Jayamukhi collegiarte club students are exbhited their mini projects and main projects on a single platform in “Abhignatha” national level technical fest organized by IEEE Jayamukhi Student branch on 23rd Feb., 2017. This Project Expo gives the future scope of the projects and encouraging to their junior students to do innovative projects in the field of mechanical engineering.

The main of team building is the action or process of causing a group of students to work together effectively as a team, especially by means of activities and events designed to increase motivation and promote cooperation in SAE INDIA Jayamukhi Collegiate club

Team building can include the daily interaction that students engage in when working together to carry out the requirements of their SAE Activities. It can also involve structured activities and exercises that students can lead.

The concept: The student selects a topic, collects information and presents a synopsis or abstract

Alignment with curriculum

• Subject from the curriculum

• Self learning

• Paper format SAE International Forma

Expectations: Basic data collection Logical reporting

Topics:• Alternate Propulsion Technologies

• Advanced Engine Technologies

• Hybrid and Electric vehicles

• Emerging Fuels and Fuel Cells

• Advanced lightweight materials

• 3R-reduse, reuse and recycle

• Dynamic modeling processes

• Vehicle Communications Network

• Vehicle dynamics and handling

• Fuel Injection Systems

• Automotive electronics

• Nano technology

• Safety and Crash

• NVH and Cabin Comfort

• Off highway vehicles

• partnerships

• Mechanical science

• Fuel economy and Co2

• Automobile Emissions and After treatments

• Energy Storage Systems and Infrastructure

• Vehicle body structures and frames

• Aero structure and technologies

• Automotive testing and instrumentation

• Vehicle architecture

• Product development tools and techniques

• Policies, regulations and standards

• Public, private and academic

The concept: Testing the general automotive knowledge of students by asking questions related to technical and other related automotive subjects

Topics:• History

• Places

• Personalities

• Technologies

• Companies

• Vehicle types and specifications

• Statistics of vehicles and so on

• All Automotive related subjects

• (as part of curriculum)

Alignment with curriculum: All automotive related subjects

Expectations:• Generic answers with aids using clue and so on

• Less questions

TEACHER’S DAY CELEBRATIONS(Sept 5th, 2017)Organized by Department of Mechanical Engineering and SAEINDIA Jayamukhi Collegiate Club

Concept:

Understanding the given concept behind each and every component.

Identify the material of the given product or components in automobiles.

Expectation:

To identify the mechanism and material behind the given component.

MI competition reflects a range of materials skills used across quality department in various automotive industries.

First round:

Materials identification

Second Round:

How Thing work -Written test of basic mechanisms

Additive Manufacturing refers to a process by which digital 3D design data is used to build up a component in layers by depositing material. The term "3D printing" is increasingly used as a synonym for Additive Manufacturing.

Purpose of the event: Additive manufacturing is an emerging technique and it is considered to be the future of manufacturing in all fields of engineering. So it is important for an Engineer to be completely aware of the developing technology.

The concept: Any component to be 3D printed is scanned and morphed in the computer with 3D modeling software’s like Autodesk etc., and then printed in the 3D printer which uses thermoplastic filaments as raw materials and a heater melts the thermoplastic and pours it in the programmed area and finishes the component, this technology is also known as FDM (Fused Deposition Modelling) or FFF (Fused Filament Fabrication). There are other methods like laser sintering, DLP etc

Expectations: Good knowledge about the process involved in additive manufacturing such as creating a CAD model, Slicing the CAD model, generating the G codes, 3D printing the same in a FDM based 3D printer and post processing the 3D printed part such as removing the supports.

Expert Speaker Name:

Dr.Gururaj Telasang, :

Scientist D, ARCI Hyderabad, :

Secretary, SAEISS Hyd Divission

Special Invitee :

Mr.M.venkateswar Reddy, :

Assoc.Professor, NREC, Hyderabad, :

Treasurur, SAEISS Hyd Divission

Additive Manufacturing refers to a process by which digital 3D design data is used to build up a component in

Students learn about the process of reverse engineering and how this technique is used to improve upon technology. Students analyze push-toys and draw diagrams of the predicted mechanisms inside the toys. Then, they disassemble the toys and draw the actual inner mechanisms. By understanding how the push-toys function, students make suggestions for improvement, such as cost effectiveness, improved functionality, ecological friendliness and any additional functionality they determine is an improvement. This engineering curriculum meets Next Generation Science Standards (NGSS).

Engineering Connection: Engineers learn about technologies, objects and systems through reverse engineering and the engineering design process. By analyzing the structure and function of a device or component, engineers can improve upon previous designs.

Pre-Req Knowledge: Students should understand that engineers use the engineering design process (see Background information under the Procedures section) to invent and improve technologies, objects and systems. In this activity, students focus on the "asking and improving" steps in the engineering design process.

Learning Objectives: After this activity, students should be able to:

Define reverse engineering as the process of disassembly and careful analysis with the goal of duplicating or improving a device or component.

Demonstrate the process of reverse engineering using a given object or component and suggest areas of improvement.

The Department of Mechanical Engineering of Jayamukhi Institute of technological Sciences Narsampet has initiated SAE INDIA Collegiate club for this academic year 2017-18 with 75 student members and two faculty advisers. Dr.V.Vikram Reddy, Professor and head is the senior faculty adviser said that SAE INDIA is the platform your bright future. Under this club we are going to conduct many events, workshops, seminars, expert lectures, industry visits, and many more technical activities for the benefit of students.

Prof.P.Rangaiah, Director of JITS, inaugurated the club and motivated students with his speechless words and he shared his childhood experiences with students by motivating and guiding every student for their bright future. Mr.B.Hemasunder, Faculty adviser given his presentation about SAEINDIA and future activities what we are going to do in detailed manner.

A one-day workshop on REVIT MEP (HVAC) is organized by future gen technologies Hyderabad. The main aim of this workshop is students will get the whole day to be hands-on with Revit MEP 2017. This workshop will be instructor led and will go through the creation, layout and editing of HVAC Ductwork, Mechanical Piping, and Domestic Piping including sloped Sanitary requirements.

This workshop is intended for the Revit user that is familiar with the software interface and is proficient with the core tools. You can bring your own laptop or rent a laptop with the software pre-loaded. Learning objectives include:

The department of mechanical engineering has arranged an industrial visit to Kakatiya Thermal Power Station for 3 rd Year students. The visit was organized with the prior permission and guidance of hon. Principal and Head of Department.

Kakatiya Thermal Power plant is located near Chelpur village of Bhupalpalle mandal in district of Telangana State. The power plant is one of the coal based power plants of TSGENCO.

This power plant has been developed in 2 stages. The first stage comprises one 500MW unit was commissioned. Unit was synchronized with grid with oil firing on 31.03.2010 at 06:08 Hrs. The Coal firing was immediately taken up and the load was raised up to 84 MW and the Unit was in service with this load for nearly about 1 hour.

Kakatiya TPP Unit-II 1X600MW, has been synchronized to grid at 03:00 hrs. on 22-10-2015 and loaded to 105 MW.

| S.No | Program Dates | Title | Sponsored By | Resource Person(s) | No.of Students Participated | Participating B.Tech. Students |

|---|---|---|---|---|---|---|

| 1 | A Three day workshop on Auto Cad | TASK | IV Year |

| Sl. No | Organizing Society | Date | Name of the Event |

|---|---|---|---|

| 1 | Department of Mechanical Engineering and JKC Hyderabad | A Three day workshop on Auto Cad |

| ORGANIZING SOCIETY | DATE | Name of the Department | Name of the Event | Name of the Organizers |

|---|---|---|---|---|

| JITS Narsampet | 6/3/2017 | Mechanical Engineering | Aero Design Challenge Workshop | Dr.V.Vikram Reddy, B.Hemasunder |

| JITS Narsampet | 22/02/2017 | Mechanical Engineering | Mechanical projects Expo- | Dr.V.Vikram Reddy, B.Hemasunder, P.Vamshi Krishna, B.Shiva Kumar |

| JITS Narsampet | 10/2/2017 | Mechanical Engineering | Industry Visit to Kakatiya Thermal Power Plant Chelpur for III year Mechanical students | B.Hemasunder, P.Ashok Kumar, N.Vishnu Murthy, M.Radhika |

| JITS Narsampet | "14-12-2016 to 20-12-2016 | Mechanical Engineering | FDP on "DOE and Optimization methods | Dr.V.Vikram Reddy |

| JITS Narsampet | 6th to 10th Sep '16 | Mechanical Engineering and JKC Hyderabad | A Three day workshop on Auto Cad | Dr.V.Vikram Reddy |

| S.No | Program Dates | Title | Sponsored By | Resource Person(s) | No.of Students Participated | Participating B.Tech. Students |

|---|---|---|---|---|---|---|

| 1 | 23-01-2015 to 24-01-2015 | A Two day workshop on Auto CAD mechanics and IC Engine design | Robosepiens technological Pvt.Ltd | 120 | II,III,IV years | |

| 2 | 28th &29th January , 2015 | Auto CAD Workshop | JKC Hyderabad | 120 | IV Year |

| Sl. No | Organizing Society | Date | Name of the Event |

|---|---|---|---|

| 1 | Robosepiens technological Pvt.Ltd, And JITS Narsampet | 23-01-2015 to 24-01-2015 | A Two day workshop on Auto CAD mechanics and IC Engine design |

| 2 | Department of mechanical engineering and JKC Hyderabad | 28 & 29 jan 2015 | Auto CAD Workshop |

| ORGANIZING SOCIETY | DATE | Name of the department | NAME OF THE EVENT | Name of the Organizers |

|---|---|---|---|---|

| JITS Narsampet | 23-01-2015 to 24-01-2015 | Mechanical Engineering | A Two day workshop on Auto CAD mechanics and IC Engine design | Dr.V.Vikram Reddy, P.Vamshi Krishna |

| JITS Narsampet | 28 & 29 jan 2015 | Department of mechanical engineering and JKC Hyderabad | Auto CAD Workshop | Dr.V.Vikram Reddy, B.Hemasunder |

| S.No | Program Dates | Title | Sponsored By | Resource Person(s) | No.of Students Participated | Participating B.Tech. Students |

|---|---|---|---|---|---|---|

| 1 | 20th Sept 2014 | Extension Lecture on " CAD/CAM and CNC Part Programming" for 3rd and 4th year Students. | SAEINDIA Jayamukhi Collegiate Club | Dr.P.Vamshi Krishna, NIT Warangal. | 120 | IV Year |

| 2 | 21st Oct 2014 | Personality Development Workshop | ISTE and JITS Narsampet | Gampa Nageshwar Rao | 120 | I year |

| Sl. No | Organizing Society | Date | Name of the Event |

|---|---|---|---|

| 1 | Department of Mechanical Engineering. | 22nd Dec to 3rd Jan 2015 | AICTE Sponsored Two Weeks Faculty Development programme on FINITE ELEMENT METHODS AND ITS APPLICATIONS |

| 2 | JITS-Wie Affinity Group | 18th Sept 2014 | Facinating Mathematics Applications to Engineering by Prof.T.K.V Iyengar |

| 3 | SAEINDIA Jayamukhi Collegiate Club | 20th Sept 2014 | Extension Lecture on " CAD/CAM and CNC Part Programming" for 3rd and 4th year Students by Dr.P.Vamshi Krishna, NIT Warangal. |

| 4 | ISTE | 27th Sept 2014 | Role of Teaching in Engineering by Prof.N.V.S.N Sharma |

| 5 | ISTE | 10th to 11th Oct 2014 | Technojits-2014 |

| 6 | SAEINDIA Jayamukhi Collegiate Club | 10th Sept 2014 | Student Convention-2014 Tier-1 Competitions |

| 7 | ISTE | 21st Oct 2014 | Personality Development Workshop by Gampa Nageshwar Rao |

| 8 | SAEINDIA Jayamukhi Collegiate Club | 10th and 11th oct, 2014 | Aero modeling And CAD Modeling Competitions in Technojits 2014 |

| ORGANIZING SOCIETY | DATE | Name of the department | NAME OF THE EVENT | Name of the Organizers |

|---|---|---|---|---|

| JITS Narsampet | 22nd Dec, 2014 to 3rd Jan 2015 | Mechanical Engineering | AICTE Sponsored Two Weeks Faculty Development programme on FINITE ELEMENT METHODS AND ITS APPLICATIONS | Prof.G.Srihari, Dr.V.Vikram Reddy |

| JITS Narsampet | 2014 (10th and 11th oct) | Mechanical Engineering | Aero modeling And CAD Modeling Competitions in Technojits | B.Hemasunder |

| JITS Narsampet | (20th Sept 2014 | Mechanical Engineering | Extension Lecture on " CAD/CAM and CNC Part Programming" for 3rd and 4th year Students by Dr.P.Vamshi Krishna, NIT Warangal. | Dr.V.Vikram Reddy, B.Hemasunder |

| JITS Narsampet | 07TH SEPT,2014 | Mechanical Engineering | Student Convention-2014 Tier-1 Competitions | Dr.V.Vikram Reddy, B.Hemasunder |

| S.No | Program Dates | Title | Sponsored By | Resource Person(s) | No.of Students Participated | Participating B.Tech. Students |

|---|---|---|---|---|---|---|

| 1 | 21st March 2014 | Industrial visit of APSRTC ZONAL WORKSHOP- Karimnagar" | SAEINDIA Jayamukhi Collegiate Club | APSRTC ZONAL WORKSHOP- Karimnagar | 120 | II,III,IV YEAR |

| 2 | 08th Feb 2014 | Extension Lecture on "Welding Process" | SAEINDIA Jayamukhi Collegiate Club | Dr.A.Kumar, NIT Warangal | 120 | III Year |

| 3 | 04th Feb 2014 | Extension Lecture on "Recent Trends in Automobile Engineering" | SAEINDIA Jayamukhi Collegiate Club | Dr.Puli. Ravi Kumar, NIT Warangal | 180 | III and IV-Year |

| 4 | 30th Jan 2014 | Extension Lecture on "Zeroth Law Of Thermodynamics" | SAEINDIA Jayamukhi Collegiate Club | Dr.AVSSKS Gupta, JNTU Hyderabad | 120 | II Year |

| 5 | 3rd Aug 2013 | Guest lecturer on''Principal Stresses And Theories Of Failure''For 3rd & 4th year students By | Dept. of. Mech, JITS Narsampet | Dr.Sridhar Reddy, JNTU Jagityal | 180 | III& IV Year |

| Sl. No | Organizing Society | Date | Name of the Event |

|---|---|---|---|

| 1 | SAEINDIA Jayamukhi Collegiate Club | 21st March 2014 | Industrial visit of APSRTC ZONAL WORKSHOP- Karimnagar |

| 2 | SAEINDIA Jayamukhi Collegiate Club | 08th Feb 2014 | Extension Lecture on "Welding Process" By Dr.A.Kumar, NIT Warangal |

| 3 | SAEINDIA Jayamukhi Collegiate Club | 04th Feb 2014 | Extension Lecture on "Recent Trends in Automobile Engineering" By Dr.Puli. Ravi Kumar, NIT Warangal |

| 4 | SAEINDIA Jayamukhi Collegiate Club | 30th Jan 2014 | Inauguration of SAEINDIA Jayamukhi Collegiate Club |

| 5 | SAEINDIA Jayamukhi Collegiate Club | 30th Jan 2014 | Extension Lecture on "Zeroth Law Of Thermodynamics" by Dr.AVSSKS Gupta, JNTU Hyderabad |

| 6 | Dept. of. Mech | 3rd Aug 2013 | Guest lecturer on''Principal Stresses And Theories Of Failure''For 3rd & 4th year students By Dr.Sridhar Reddy, JNTU Jagityal |

| ORGANIZING SOCIETY | DATE | Name of the department | NAME OF THE EVENT | Name of the Organizers |

|---|---|---|---|---|

| JITS Narsampet | (21st March 2014) | Mechanical Engineering | Industrial visit of APSRTC ZONAL WORKSHOP- Karimnagar | B.Hemasunder |

| JITS Narsampet | (08th F 2014) | Mechanical Engineering | Extension Lecture on "Welding Process" By Dr.A.Kumar, NIT Warangal, | Dr.V.Vikram Reddy, B.Hemasunder |

| JITS Narsampet | (04th Feb 2014) | Mechanical Engineering | Extension Lecture on "Recent Trends in Automobile Engineering" By Dr.Puli. Ravi Kumar, NIT Warangal | Dr.V.Vikram Reddy, B.Hemasunder |

| JITS Narsampet | (30th Jan 2014) | Mechanical Engineering | Inauguration of SAEINDIA Jayamukhi Collegiate Club | Dr.V.Vikram Reddy, B.Hemasunder |

| JITS Narsampet | 30th Jan 2014) | Mechanical Engineering | Extension Lecture on "Zeroth Law Of Thermodynamics" by Dr.AVSSKS Gupta, JNTU Hyderabad | Dr.V.Vikram Reddy, B.Hemasunder |

| S.No | Program Dates | Title | Sponsored By | Resource Person(s) | No.of Students Participated | Participating B.Tech. Students |

|---|---|---|---|---|---|---|

| 1 | 20th Dec 2012 | National Seminar on Geometrical Tolerances by. | Dept. of. Mech, JITS Narsampet | Dr.P.Madar Valli From Gitam University | 180 | III& IV Year |

| 2 | 12th Sept, 2011 | Personality Development Workshop | ISTE, Student Chapter | Sri Gampa Nageshwar Rao | 180 | I& II Year |

| 3 | 19th Jan, 2012 | Personality Development Workshop | ISTE, Student Chapter | Dr.Pattabhiram | 350 | I, II, III& IV Year |

| 4 | 18th to 20th Jan, 2012 | 3 Days Workshop on AutoCAD | JKC & Autodesk | 120 | III year |

| Sl. No | Organizing Society | Date | Name of the Event |

|---|---|---|---|

| 1 | Dept. of. Mech, Jits Narsampet | 20th Dec 2012 | National Seminar on Geometrical Tolerances by Dr.P.Madar Valli From Gitam University. |

| 2 | ISTE Student Chapter | 24th & 25thAug, 2010 | Technojits-2010 |

| 3 | ISTE Student Chapter | 11th & 12th Aug, 2011 | General Quiz & Essay writing Competition |

| 4 | ISTE, Student Chapter | 12th Sept, 2011 | Personality Development Workshop by Sri Gampa Nageshwar Rao |

| 5 | ISTE, Student Chapter | 19th Jan, 2012 | Personality Development Workshop by Dr.Pattabhiram |

| 6 | JKC & Autodesk | 18th to 20th Jan, 2012 | 3 Days Workshop on AutoCAD |

| ORGANIZING SOCIETY | DATE | Name of the department | NAME OF THE EVENT | Name of the Organizers |

|---|---|---|---|---|

| JITS Narsampet | (3rd Aug 2013) | Mechanical Engineering | Guest lecturer on''Principal Stresses And Theories Of Failure''For 3rd & 4th year students By Dr.Sridhar Reddy, JNTU Jagityal | Dr.V.Vikram Reddy, B.Hemasunder |

| ORGANIZING SOCIETY | DATE | Name of the department | NAME OF THE EVENT | Name of the Organizers |

|---|---|---|---|---|

| JITS Narsampet | 14-12-2016 to 20-12-2016 | Mechanical Engineering | FDP on "DOE and Optimization methods | Dr.V.Vikram Reddy |

| JITS Narsampet | 22nd Dec, 2014 to 3rd Jan 2015 | Mechanical Engineering | AICTE Sponsored Two Weeks Faculty Development programme on FINITE ELEMENT METHODS AND ITS APPLICATIONS | Prof.G.Srihari, Dr.V.Vikram Reddy |

Sri.Ch.Narsimha Reddy, Chairman

Sri.Ch.Devender Reddy, Secretary

Sri.T.V.R.N.Reddy, Joint Secretary

Dr.M.Lokanadha Rao, Professor

Prof.P.Rangaiah, Professor

Dr.G.Srihari, Professor, MED

Prof.G.Sathaiah, Dean Academics

Dr.G.Krishna Murthy, Director, MBA

Dr.V.Vikram Reddy, Professor & Head, MED

Mr.P.Ashok Kumar, Assoc.Prof.,MED

Mr.N.Vishnu Murthy, Asst.Prof,MED

Mr.M.Jawahar, Asst.Prof,MED

Mr.M.Shashidhar, Asst.Prof,MED

Mr.M.Srikiran, Asst.Prof,MED

Mr.V.Raja Rao, Asst.Prof,MED

Mr.B.Shiva Kumar, Asst.Prof,MED

Mr.P.Vamshi Krishna, Asst.Prof,MED

Mr.B.Hemasunder, Asst.Prof,MED

Mr.B.Sandeep, Asst.Prof, MED

The inaugural session for Faculty Development Programme was held on 14th Dec, 2016. The president of the function Prof.P.Rangaiah, Director, Jayamukhi Institute of technological sciences has conducted the proceedings.

Sri.T.V.R.N.Reddy, Joint Secretary, Jayamukhi Institute of technological sciences has welcomed all dignitaries, Heads of Department of various faculties and participants. He has advised all participants to take full advantage of this programme, to enhance their knowledge and effectively implement in their respective colleges and improve the quality of engineering education.

Dr.V.Vikram Reddy, Coordinator for the faculty development programme has submitted a brief report and explained the technical significance of faculty development programme on “Design of Experiments and Optimization Methods”.

The Guest of honor for the inaugural session Dr.M.V.Satish Kumar, Professor in Mechanical engineering department, KITS (S) Huzurabad has delivered the inaugural address and has explained the significance of Faculty Development Programme and He also delivered the keynote address on “Design of Experiments and Optimization Methods”.

Prof.M.Lokanadha Rao, Principal, Jayamukhi Institute of technological sciences has addressed the gathering and advised the participants to improve knowledge, technical skills for Design of Experiments.

The Faculty development programme is intended to provide opportunities for faculty members employed in engineering colleges for their knowledge upgradation and skills.

The Design of Experiments and Optimization Methods is important for every experimenter has to plan and conduct experiments to obtain enough and relevant data so that he can infer the science behind the observed phenomenon. It also helps in reduce the time and material cost in research works.

The present Faculty development programme provides platform to the faculty members of various technical institutions to know concepts of DOE and its applications for solving a variety of practical engineering problems.

As participants are expected from all over India, this course would provide an excellent opportunity for the participants to interact with one another and discuss problems and solutions of mutual interest.

This Faculty development programme helps faculty members to pursue research and help in sharing the knowledge to the fellow colleagues and students.

Technical sessions were conducted by highly qualified and experienced persons from National Institute of Technology (NIT) Warangal, Kamala Institute of technology and Science (S) Huzurabad and Jayamukhi Institute of Technological Sciences Narsampet.

Dr.M.V.Satish Kumar, Professor and Head in Department of Mechanical Engineering, KITS (S) Huzurabad has delivered a series of lectures and introduced concepts of Design of Experiments and Optimization Methods.

Dr. A.Kumar, Associate Professor in Mechanical Engineering Department, NIT Warangal has delivered a series of lectures on Design of Experiments using Taguchi Methods and its case studies

Dr. V.Vikram Reddy, Professor and Head of the Mechanical Engineering Department, JITS Narsampet has delivered a series of lectures on Design of Experiments using RSM, Optimization using Taguchi based DEAR Method

Dr. M.Lokanadha Rao, Principal and Professor in Department of Mechanical Engineering, JITS Narsampet has delivered a series of lectures on DOE and Data Analysis Case Studies.

Dr. M.Lokanadha Rao, Director, JITS Narsampet has delivered a lecture Practices for Effective Teaching and Learning Processes.

Dr.G.Srihari, Professor, Mr.P.Ashok Kumar Associate Professor and Mr.N.Vishnumurty Assistant professor, of Mechanical Engineering Department, JITS Narsampet have delivered a series of lectures on Optimization using GRA Method, Case Studies GRA Method, ANOVA and Regression Analysis.

The valedictory session for the One week Faculty development programme was held, in which Prof.P.Rangaiah, Director, Jayamukhi Institute of Technological Sciences has conducted the proceedings of the valedictory session

Dr.V.Vikram Reddy, Coordinator for the One week Faculty development programme on “Design of Experiments and Optimization Methods” has presented a report on the programme.

Several Participants of the programme and faculty members of the department have given a feedback on this programme and have expressed their satisfaction, about the hands on experience; they had during laboratory session and expressed their gratefulness to JITS Narsampet for Sponsoring the FDP Programme.

Sri.T.V.R.N. Reddy, Joint Secretary and Prof.P.Rangaiah, Academic Director, Jayamukhi Institute of Technological Sciences have expressed their satisfaction over the organization, arrangements and appreciated the participants for their keen interest, active participation during technical and laboratory session, effective interaction with the resource and their regular attendance to all the technical and laboratory sessions.

Dr.P.Lokanadha Rao, Principal has delivered the valedictory address and appreciated the participants and organizing committee of FDP. And he has given certificates to the participants and course materials.

Prof.P.Rangaiah, Director, Jayamukhi Institute of Technological Sciences has delivered the presidential address and thanked JITS Narsampet, for sponsoring this One week Faculty Development Programme.